The Guided Auger Boring Process

See our Guided Auger Boring method video at the bottom of this page.

Directional Auger Boring is a technique whereby product is installed between two prepared shafts, usually manholes.

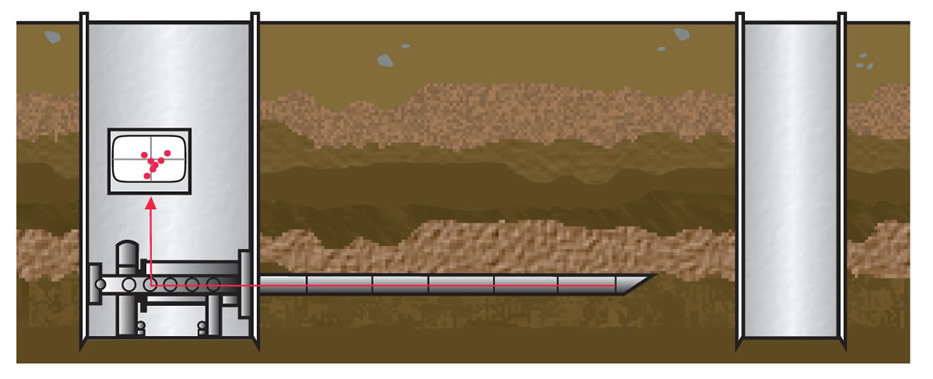

The auger boring rig is set up in the launch shaft and the laser guided probe is then jacked through the ground to the reception exit shaft.

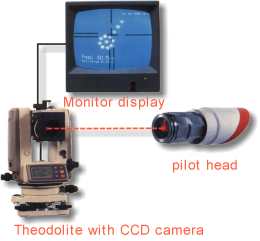

Assisted by pilot rods equipped with optical passage, steering head, and theodolite with CCD camera and monitor, open-guided auger boring can be carried out in displaceable ground. The pilot pipe is pushed through the ground towards the target shaft. The direction is monitored by the CCD camera throughout the whole process. The direction of the head is adjusted by rotating the pilot pipes to guide the steering head on the cross hair image on the guidance monitor.

Dependent on the length of the bore, torque problems may arise in wet or compacted cohesive soils. Bohrtec developed a double-walled pilot rod. The double pilot rod allows the internal rod to turn the steering head; whilst the outer steel sleeve takes all the ground friction.

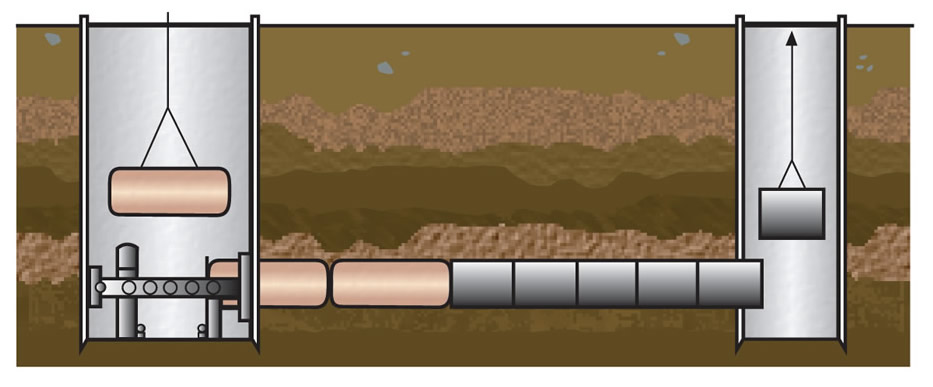

The precision-guided bore made by the pilot pipe is then followed by the steel cased auger sections which enlarges the bore to the same size as the product pipes.

The product pipes are then jacked through whilst the casings are being retrieved in the reception pit.

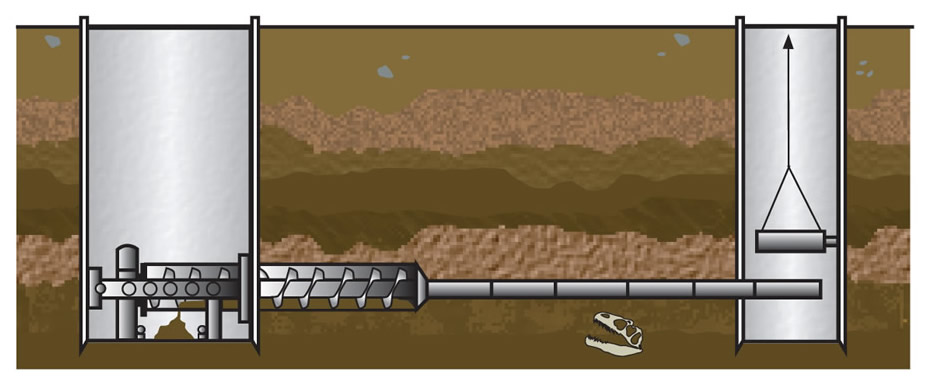

Alternatively the product pipe can be jacked directly by using an extension kit. The soil is transported through the steel pipes to the reception shaft by reversing the rotation of the augers.

Possible applications

- In all displaceable soils; with the water auger and double wall pilots, even under ground water

- Up to 80m drive length

- DN 150 – DN 450

Application limits:

- Heavily compacted soils or medium to dense rock

- Obstacles > 80 mm

Measuring Technology

The guidance system consists of three components:

- A LED target in the pilot head

- A theodolite with a special camera

- A monitor mounted in the shaft adjacent to the operators position

Guided Auger System for larger diameter pipes

For larger bores, the use of a steerable auger is recommended. The auger drill tool has a steerable lead section, which houses a LED target. As with the pilot bore method, an optical passage through the auger sections allows the Theodolite CCD camera to monitor the deviation of the head from the intended bore axis.

At the end of the guided auger boring sequence, the product pipes, which have the same outer diameter as the casings – auger sections, will be pushed through. Larger product pipes may be used after the bore has been enlarged using an extension kit for product pipes of a larger diameter. The product pipes will push the extension kit ahead. The extension kit has a direct drive connected via hydraulic hoses, back through the product pipes to the hydraulic power pack at the launch shaft.

When pushing the product piping through, the augers are reversed and the soil removed during the reaming is conveyed to the target shaft where it would be collected and removed along with the casings (auger sections) which are pushed into the target shaft as the product pipes are added at the launch shaft.

Possible applications

- In all cohesive, sandy and gravel type soils

- Up to 80m drive length

- DN 150 – DN 800

Application limits:

- Obstacles > 120 mm

AMS Trenchless is seen as one of the leading Guided Auger Boring Suppliers. See our Guided Auger Boring Technique or our Guided Auger Boring Case Study.